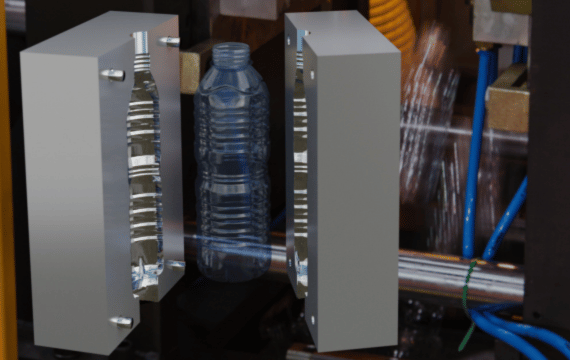

Plastic Bottle Manufacturing

For more than 15 years in business, EMW Pack Co., Limited has developed into a proficient manufacturer with a focus on producing plastic bottles and goods for different applications. Some examples includes cosmetic bottles such as lotion pumps, travel sets, trigger sprayers, plastic caps, and more. With full manufacturing line that includes everything from product design to commodity manufacture and assembly, we are capable of creating various types of plastic molds and production. We look forward to working with you soon!

Wow Your Customers with Outstanding Plastic Bottles

In the dynamic world of consumer goods, packaging plays a pivotal role not just in product protection but also in crafting a memorable and delightful experience for customers. Plastic bottle packaging, with its versatility and design possibilities, offers an exciting avenue for brands to connect with consumers on a whole new level. EMW PACK is a professional manufacturer of custom plastic bottles and we will be happy to work with you to create the product packaging you need to help succeed in your business.

Role Of Plastics In Packaging Bottles

Plastic bottles and jars account for over 75% of all plastic containers by weight. PET and high density Polyethylene (HDPE) accounts for about 86 percent of the plastic container market and can be used for bottling. Other forms of plastics including bioplastics and recycled plastics are utilized for a large range of bottling and packaging demands in a multitude of industries, and are recyclable.

PET is extensively used to make portable plastic bottles and other plastic containers. PET, which is made from crude oil, is also used to make most plastic water bottles. Examples include PET soda bottles, water or beverage and jars.

HDPE is the safest plastic material to use for food and drink storage. It is currently one of the most versatile plastic materials used for a lot of different things, such as HDPE bottle milk jugs, shampoo bottles, and supplement jars.

PVC bottles are less common than PET or HDPE bottles and are primarily used for products such as detergents, cleaners, and chemicals. It is also utilized in medical applications due to its resistance to pathogens and ease of disinfection.

LDPE bottles are a popular type of plastic bottle used for packaging products such as shampoo, lotion, and other personal care items. LDPE is an ideal choice for packaging applications that require flexibility and durability.

It is more heat resistant than others, best suited for food packing and storage, designed to store hot products or be heated. Flexible enough to bend, yet it holds its shape and strength for long period. Ex: PP Bottle caps, prescription bottles, etc.

Other bottles are plastic products made from PC, LEXAN, or BPA plastic materials. They are not commonly used in manufacturing due to their high ability to leach chemicals but still widely used for baby bottles and water coolers.

Plastic Bottles By Shapes

We can manufacture plastic bottles in many different unique shapes including classic Boston Rounds, Cosmo Rounds, Cylinders, Ovals, Wide Mouth Rounds and Pharmaceutical Rounds, Square, Oblong or even specialty shaped bottles.

Plastic Bottles by Purpose

There are many different types of plastics on the market that are designed for specific uses. Each type has distinct characteristics. There are plastics that can even be bacteria-resistant and best to use for food packaging and life-saving medical equipment. Contact EMW PACK to discuss with you.

EMW PACK PACKAGING BOTTLES ADVANTAGE

Cost efficient to be less expensive than others

We deliver and fulfill your order on time and in full.

Screen Printing On Packaging Bottles

Screen printing, often known as silk screen printing, is one of the most widely used decorating methods on plastic bottle packaging. Screen printing is a type of ornamentation where ink is physically printed onto a container, as opposed to labeling.

Hot Stamping On Packaging Bottles

Hot stamping, sometimes called foil stamping or roll stamping, is a decoration method that’s frequently applied to goods that have an upscale appearance. To make your plastic bottle packaging stand out, a metallic foil or design is “rolled” onto the plastic container.

Shrink Sleeve Labeling On Packaging Bottles

As the name implies, shrink sleeve labeling is the technique of labeling a container by applying a whole “sleeve” label. After that, the label is shrink-wrapped onto the plastic bottle and heated or steamed. Shrink sleeves provide you a lot of versatility and let you create the label around the entire plastic bottle packaging.

Why Choose Us To Customize Your Packaging?

EMW PACK welcome the opportunity to work with you to develop a product that addresses your individual requirements. Our skilled technicians are experts when it comes to plastic bottle packaging technology and craftsmanship. From simple containers to complex structures, we have the capability to create a unique design that will meet your needs and exceed your expectations.

Advantages To Work With Us

Tell your brand story through custom plastic bottle packaging. You can discuss your particular needs in an obligation-free consultation and thereby find a suitable product to accommodate you. Contact EMW PACK now!

We are your single source for all your plastic bottle needs. We specialize in creating and manufacturing high-quality plastic bottle packaigng to protect and showcase your product. Our skilled team will collaborate to determine your needs.

Latest Product Display On Packaging Bottles

Acrylic bottles are highly transparent and offer excellent clarity, which allows for easy viewing of the contents inside. They are much lighter than glass bottles, which makes them easier to handle and transport.

Airless bottles are, by their very nature, sophisticated in their appearance. However, brands can optimize the look and feel of their bottles through a selection of customizable options including color, size, labeling, and spray finishes.

These bottles feature a trigger mechanism that, when pressed, releases a fine mist or stream of the contained liquid. They come in various sizes and designs, with adjustable nozzles to control the spray pattern and volume. Typically made from durable plastics like PET or HDPE, trigger spray bottles are chosen for their strength and compatibility with a wide range of liquids, including cleaning solutions, disinfectants, and household chemicals.

E-liquid or vape juice bottles are compact, portable and specialized containers designed for storing and dispensing e-liquids used in electronic cigarettes or vaping devices. These bottles are typically made from durable plastics such as PET or LDPE, chosen for their compatibility with e-liquid ingredients and resistance to leakage. E-liquid bottles often feature child-resistant caps or tamper-evident seals to ensure safety and compliance with regulations

Medicine pill plastic bottles are essential containers designed for storing and dispensing pills, tablets, or capsules. These bottles are typically made from high-quality plastics such as HDPE or PET, chosen for their durability, chemical resistance, and compatibility with pharmaceutical products. They bottles can be customized with labeling or printing to display important information such as dosage instructions, expiration dates, and product names.

The soft touch cosmetic tube is made from LDPE, but the surface is covered with a layer of soft rubber material, that gives a soft-to-the-touch feel. This coating is also known to resist scuffs and fingerprints left behind from handling the product.

- Gallery

- Manufacturer

Related Products on Plastic Bottle Packaging

Size, material, color, printing details, surface finish, quantity, shipping destination, etc. You can also just tell us your requirements and we will recommend products to you.

AI, PDF, PSD high resolution JPG or PNG.

Yes. Stock samples if available are free, but you would need to pay for the delivery fee. If the sample is customized, we will need to charge you for the sampling fee.

Yes, we can match your color. Before printing for mass production, we will first have color matching with Pantone color number by ourselves, or we could schedule a video call to check color if you have free time.

Depending on the order quantity and production details. Normally it will take 3~4 weeks. However we always do our best to deliver the goods the soonest possible time.