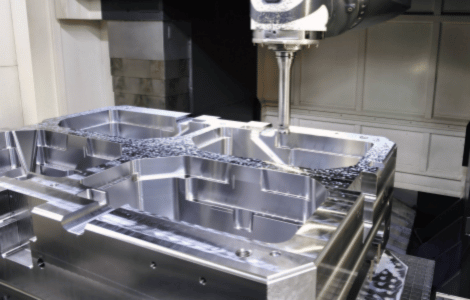

Plastic Mold Specifications

| Size: | Customized |

|---|---|

| Steel Material: | P-20, H-13, Stainless Steel, Pre-Hardened Steel, Hardened Steels or as requested |

| Cavity: | Single to Family mold and Multi-Cavity Designs |

| Plastic Material: | ABS, PP, PE, HDPE, POM, PMME, Acrylic, Nylon, PS, PET or as requested |

| Surface Finish: | EDM, Texture, High Polish, SPI Finish |

| Secondary Operations: | Printing, Painting, Texturing, Ultrasonic Welding, Assembly |

| Leadtime: | 30~50 days depending on complexity, design and size |

| Industry Applications: | Packaging, Personal Care, Consumer Goods, Medical Devices, Electronics, Automotive, etc |

Moldmaking Through The Years

We can make all types of injection molds, blow molds, EPS molds from less expensive, shorter-run aluminum tooling, to very high production, hardened steel tooling. We produce molds for very simple parts, or for very detailed, intricate pieces since 2015. Contact EMW PACK now!

Popular Products

Bottle caps are produced by Injection molding process. We can design and build a single, multi-cavity or family mold with cold runner or hot runner injection. Send us your inquiries and requirements!

Dishwashing liquid bottles are produced by Blow molding process. We choose the optimal blow molding process for every product we produce as we commit to deliver perfect bottles each time.

EPS Styrofoam cushion are made by pre-conditioning the raw materials before their final “tooled” molding process, necessary for creating EPS products. We use aluminum for the mold.

Lotion tubes are produced by extrusion molding process. Our extruded lotion tubes offer a polished seamless look that is ideal for cosmetics, beauty, personal and home care.

Designed and built by Compression molding. We offer rubber molding in a wide range of standard rubber products as well as custom options for those more complex and difficult jobs.

Blister packaging trays are made by Vacuum Molding process. A blister mold, is a tool used in blister packaging to create the raised plastic cavities that hold the products.

Glass Bottle Skincare Series

We would like to offer our glass manufacturing capability for different glass bottle styles in various colors, capacities, and neck finishes for your glass bottle skincare series.

Plastic Skincare Series

We specialize in providing customized solutions for plastic skincare series, cosmetic packaging needs, including health, skincare and beauty products.

Cosmetic Tubes Series

We can develop a custom plastic package such as cosmetic tubes or guide you on the most compatible product and material to choose for your business.

Customization Option

In a crowded marketplace with fierce competition, you need every advantage you can get to make your business stand out from the crowd, like building brand recognition, and inspire customer loyalty. Customizing your packaging is powerful to provide the perfect vehicles for communicating with your customers and we can help you with that. All of our molds for packaging products are export compliant and can be shipped all over the world. Allow us, EMW PACK to help you.

“The Future of Moldmaking in Packaging”

Moldmaking, a cornerstone of the packaging industry, has the potential to completely change how we create, manufacture, and use packaging solutions in the future. Plastic mold manufacturing technologies are at the forefront of advancing innovation to satisfy the changing needs of the packaging industry. Demands for efficiency, personalization, and sustainability will continue to transform the packaging landscape.

Each project is unique, so we require varying amounts of time to build molds. The lead time for molds fabrication depends on the complexity of the mold. Mold builds can vary from 4 weeks to 2 months depending on the project complexity.

First we will discuss with you to go over your project in detail, reviewing your product concepts and quantity needs in order to select the right materials. We then provide you with a price quote for the mold and for the injection or blow molded parts.

For new and customized product, a prototype is a quick way to find out if you are on the right track with your plan or design. It is often the best way to gather feedback from users while you are still refining your design.

You need to provide us size, material, printing details, quantity, shipping destination, and your 3D data. You can also just tell us your requirements and we will recommend products to you.

Lower quantity like 500pcs is acceptable but the more quantity means better pricing. We highly recommend to start at 10,000pcs per design.