3D Printing Service

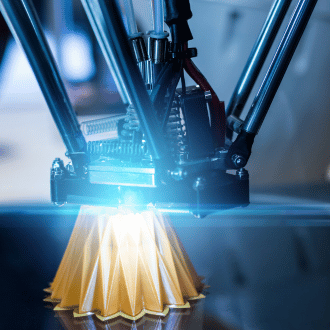

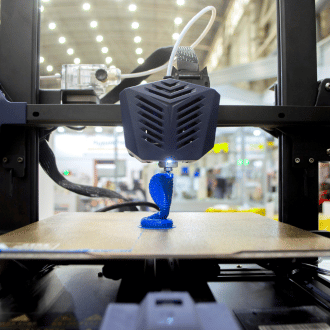

The process of turning a computer model into a tangible, solid object is known as 3D printing or a term used to refer to additive manufacturing. Due to the fact that pieces must be created by layering materials one after the other, it is also known as additive fabrication. This is another service that EMW Pack provides, so please message us with the details of your unique 3D printing needs!

Try our Amazing 3D Printing Service

EMW Pack is your 3D printing reliable source. For your company and particular needs, we can provide tailored or standard 3D printing services. Please get in touch with us right now!

3D Printing by Applications

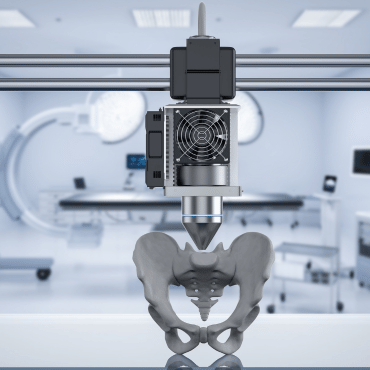

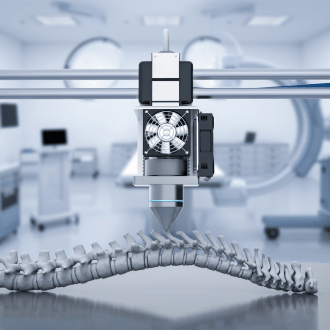

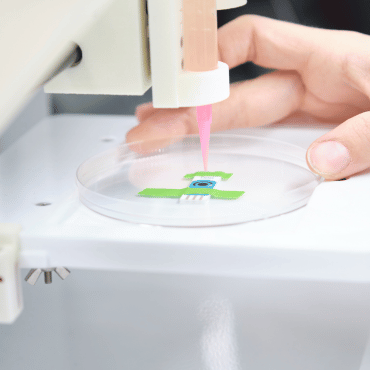

3D printing plays a significant role in the medical and healthcare industry. Before executing a complex procedure on a patient, for example, surgeons can practice it on 3D printed models. This lowers the possibility of surgical errors and enhances results.

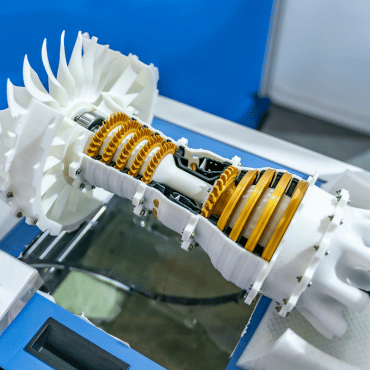

3D printing accelerate innovation in the aerospace and aviation industry. It is utilized for a variety of purposes in the aerospace component lifecycle, such as tool development and validation, end-use parts in jet engines, aircraft interiors, jigs for maintenance, and design prototypes.

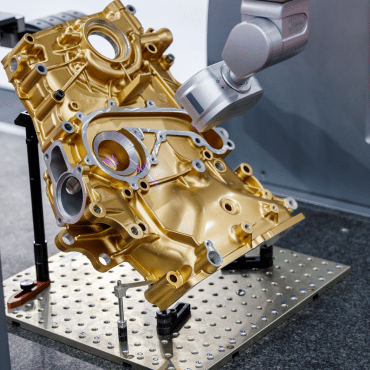

Faster testing, iteration, and design modifications of automotive assemblies and components are made possible by 3D printers, which quickly create prototypes in a matter of hours. 3D printing for automotive results in productive and successful product development.

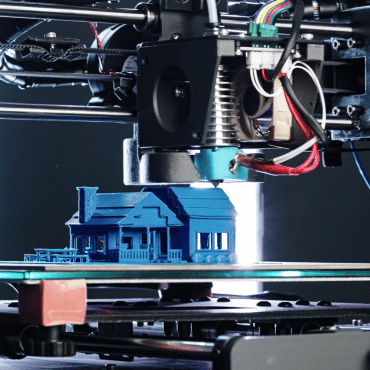

3D printing for Construction offers more design flexibility and enhanced functionality by customizing parts and components for certain projects. Since parts and components may be created swiftly on-site, it expedite construction process that results in faster completion.

3D printing for Engineering enables engineers to solve issues and find answers without ever leaving their work locations by using 3D printing to manufacture new prototypes, even ones with intricate interior structures and geometries.

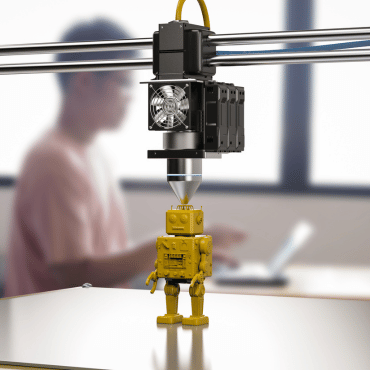

Toy repairs, creating replacement component, and customized toy creation are all possible with 3D printing technology. With the help of 3D-printed toys, we can create customized play experiences for kids that encourage their imagination and sense of ownership.

3D printing helps you get from the idea to the product in just a matter of days. While 3D printing is mostly utilized for creating prototypes, it may soon be applied to the mass production of products like integrated circuits and optical sensor packaging.

3D printing for research allows researchers to quickly translate their ideas into physical prototypes. Scientists can now iterate and improve their designs more quickly. 3D printing has also advanced as a research tool for the discovery and design of new materials.

EMW PACK: Your Premier Provider of 3D Printing Services

EMW Pack provides 3D printing solutions for your needs. We are located in China with state-of-the-art facility and manufacturing lines. We guarantee that you will receive excellent and high-performing 3D printing services from us.

Automotive parts remodeling, engineering, medicine, architecture, manufacturing, toy manufacture, and many more fields find custom 3D printing services to be highly advantageous. Ask us for an estimate based on your particular needs!

Custom 3D Printing Solution to Strengthen Your Brand

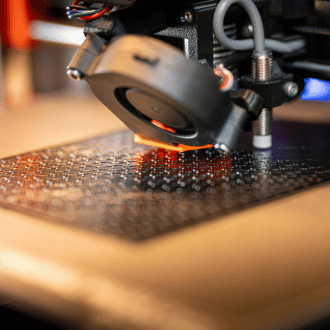

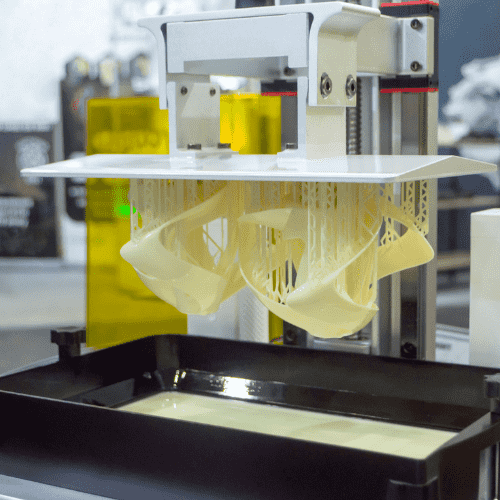

The first method used in industrial 3D printing was stereolithography (SLA). SLA printers are excellent at creating parts with precise dimensions, flawless surface finishes, and tight tolerances. They can also help with the function of the part, by testing how well an assembly fits together. Widely used in the medical field.

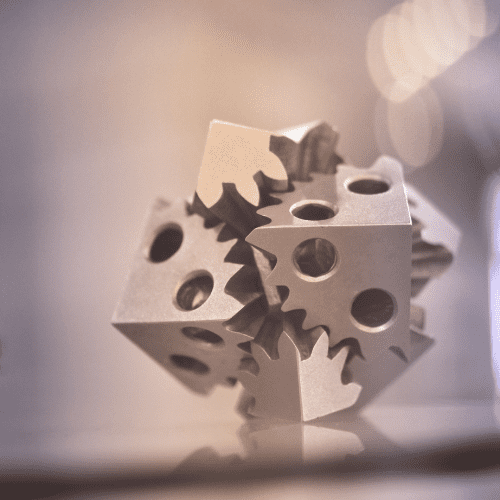

Selective Laser Sintering (SLS) creates solid plastic by melting granules based on nylon. SLS parts are robust, appropriate for functional testing, and able to accommodate snap-fits and living hinges because they are constructed from genuine thermoplastic material. Parts are stronger than in SL, although surface finishes are rougher.

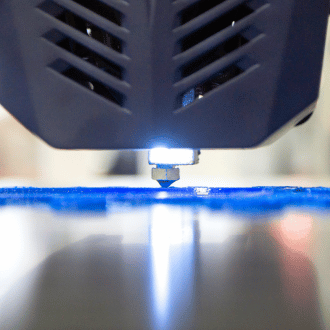

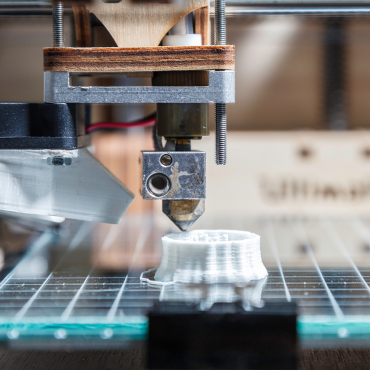

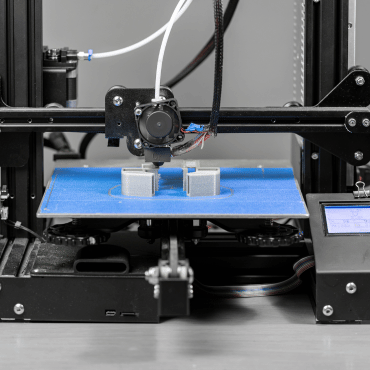

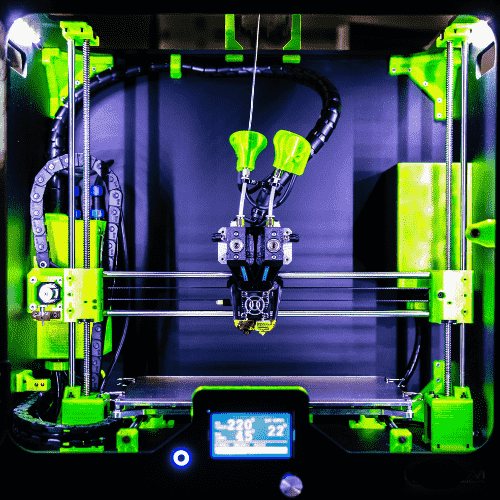

Fused deposition modeling (FDM) is a common desktop 3D printing technology for plastic parts. Layer by layer, plastic filament is extruded onto the build platform by an FDM printer. It’s a simple and affordable way to create real models. The regular FDM filaments are by far the cheapest 3D printing material, compared to other 3D printing methods,

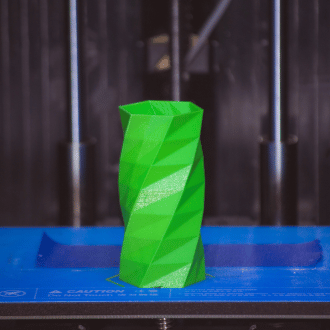

- Gallery