EMW PACK MOLDS

Are you ready to take your products to market? Do you need plastic molds or Die cast parts? From concept to completion, EMW PACK helps to manufacture what you’ve developed, and realize your big ideas or existing formulas into viable finished products. Contact us to learn how we can help you take your project to the next level.

Production Molding

The process of producing complex pieces in large quantities using thermoplastic pellets is known as production molding. Without it, things like phone cases, electronic housings, toys, and even car parts would not be possible. EMW PACK is a full-service company offering different processes in custom molding / manufacturing. Our dedicated mold designers, toolmakers and technicians are able to create the best mold design for your project.

EMW PACK Co., Ltd. is a team of talented people and highly skilled professionals founded on the concept of management, customization, convenience and total quality service. We offer full service processes for your business from prototyping to production to assembly.

Various Molding Techniques

The world of molding is diverse, utilizing various techniques each suited to specific applications and materials.

The Injection molding process is a go-to method for mass production, if you need lots of pieces, particularly with plastics. Our injection molding machines are efficient and we can produce even complex part shapes for you.

Blow molding creates hollow products from thermoplastic materials using preforms. Our blow molding machines are capable in producing simple to high-end bottles or your customized product shape.

An ideal process for large and complicated parts. With our expertise and experience, our team of compression molding professionals can create intricate, high-quality parts with speed and efficiency.

For larger and more complex objects, we can produced using thermoforming method. We can tackle larger volume projects as well as smaller projects with our expert teams. Our talented people has wide range of material knowledge.

This technology produces a wide range of products for many industries. Materials we normally use in Vacuum forming plastics are ABS, HDPE, Polyethylene, PET, Polypropylene, Polycarbonate, etc.

Pipes, hoses, drinking straws, rods, are all produced by the extrusion process. The shape of the die determines the shape of the tube. Our expertise in tubes remains unrivaled. Allow us to deliver value to your business!

Insert molding is a process where a pre-made part is placed into a mold and then encapsulated with a plastic resin. We have molded many plastic parts with metal inserts and our skillful technicians are very familiar with this process.

Overmolding is when two or more components are molded on top of one another during the injection molding process. Some samples of overmolding that we did includes toothbrush with a plastic and rubberized grips on the handle.

Materials Used In Molds

When it comes to molding, material selection is just as important as the actual procedure. The choice of material is crucial to the manufacturing process since each one has unique qualities, difficulties, and uses.

Industries Served

Many industries have adopted molding, each making use of its advantages in a different way. The impact of molding technology is wide and varied, ranging from kitchenware to automotive.

EMW PACK CUSTOM MOLD ADVANTAGE

Designed and build for long term production

Highly specialized technique to meet high precision projects

Consistent ability to replicate identical parts over and over.

Efficient and effective molding reduce costs.

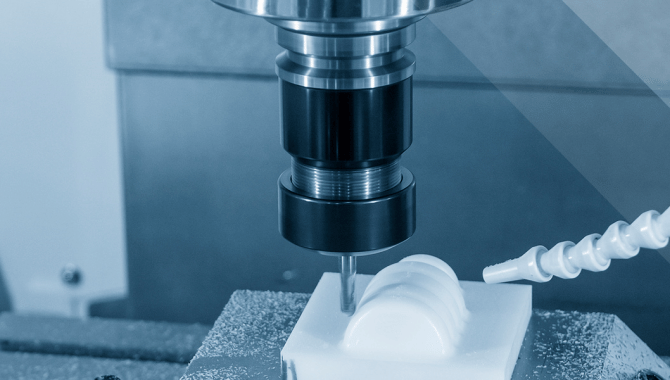

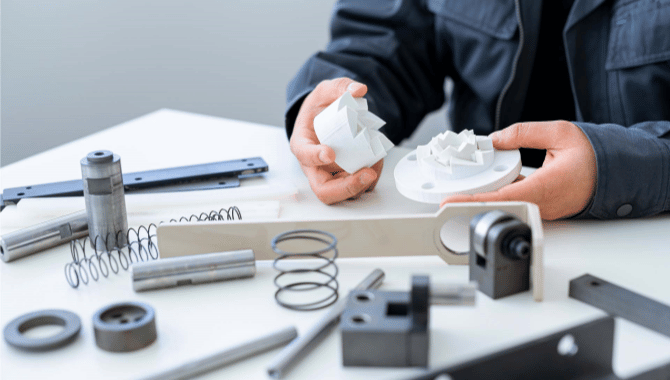

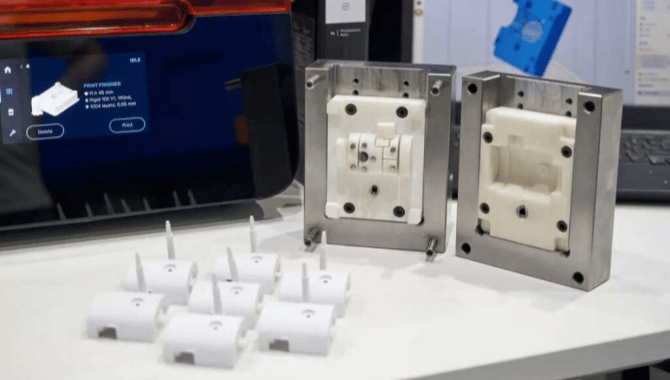

Rapid Prototyping

Rapid prototyping often produces one or a small number of functional prototypes. By using methods like 3D printing and CNC prototyping, rapid tooling can drastically cut down on mold development and manufacturing timelines. Contact us for more info about this service.

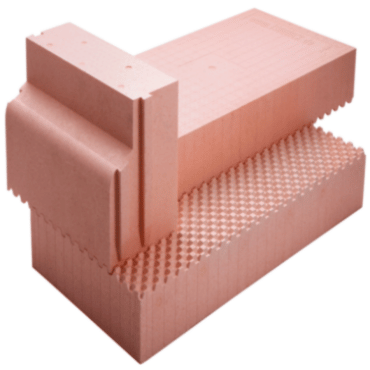

EPS Mold Manufacturing

The production of EPS products requires that the raw materials be pre-conditioned prior to their final “tooled” moulding process. The conversion process is carried out in three stages: Pre-Expansion, Maturing and Final Forming. Our EPS parts were mostly cushions to protect many appliances.

Rapid Tooling

EMW PACK offers prototype injection molding and tooling services for many years. We are able to save our customers both time and money by providing molds built with aluminum or softer steels reducing overall tooling cost and lead times.

Why Choose Us To Customize Your Packaging

EMW PACK provides a full range of different packaging services. Over nearly 15 years in the business, we are aware that each person has particular demands. We provide custom molding services to meet a wide range of needs. We are able to make molds that are specially designed for your requirements. To learn more about our packaging production capabilities, contact us or request a quote now.

Advantages To Work With Us

We are a full-service provider, capable of handling all aspects of the production process, from design and prototyping to tooling and packaging. Our solutions are designed to streamline your supply chain.

We use an on-demand strategy to enable just-in-time manufacturing, guaranteeing that the custom injection molded parts you order will arrive exactly when you need them.

Latest Product Display

The only practical way to make bottles and jars is by blow molding. This method is also used for large plastic containers such as drums. If you require a large quantity of stock in a short period of time, blow molding is a better option than injection molding.

Normally uses a hot runner injection molding system to manufacture plastic caps and closures. This method injects molten liquid plastic directly into mold cavities, where the material takes the shape of the mold.

Most common examples of Thermoforming Food Packaging are plastic trays, cups, containers and clamshells. These container solutions attractively display and protect consumable products, and they are products used by consumers in daily life.

- Gallery

- Manufacturer

Related Product

Depending on your product requirements. It generally takes a month to make a mold. Then production time also depends on the quantity needed. We can provide all details once we receive your CAD data and specifications. For prototype samples it depends on your order quantity, small pilot run can be done within one week, once the mold is ready.

Contact us to discuss your idea and how we can help you with. If you have an initial artwork, you may send it to us and our artwork team will review it. Then we will reach out to you to discuss which process is the most suitable, corrections or modifications before proceeding further.

Yes. Also, we provide samples with your color requirement prior to mass production. Before the item like bottles or caps are molded, we will do a trial molding and send you a sample thru express air courier like DHL or FEDEX so you can review your product first.

Yes, we can match your color. Before molding for mass production and printing when required, we will send you samples for approval.

Yes, we can design and build a mold based on your product requirement. We will do an initial mold trial to provide you a sample upon completion of the mold, of your product in your chosen color, so you can review the color, dimension and quality prior to mass production.