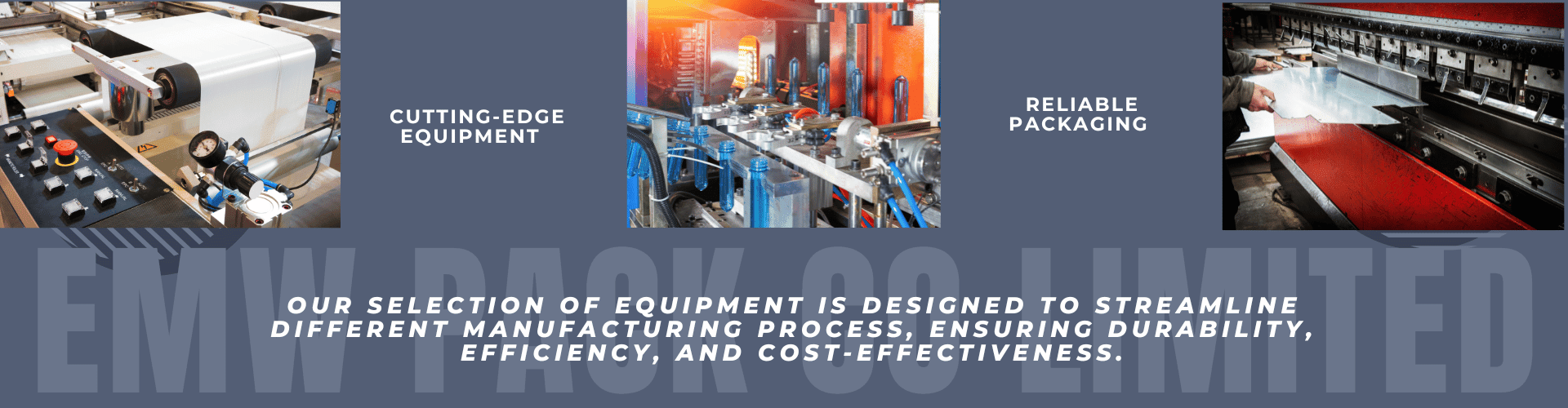

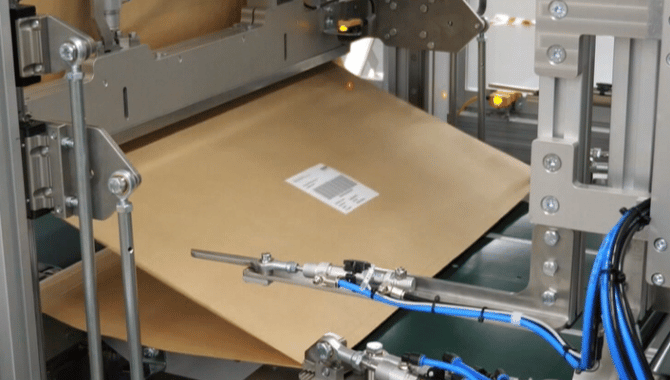

Equipment for Paper Packaging

Welcome to our comprehensive range of equipment for paper packaging. We understand the importance of efficient and reliable packaging solutions for your business. Our selection of equipment is designed to streamline our paper packaging process, ensuring durability, efficiency, and cost-effectiveness.

Categories of Equipment:

- Paper Cutting Machines: Precision cutting machines to customize paper sizes according to your packaging needs.

- Folding and Gluing Machines: Automated systems for folding and gluing paperboard, ensuring secure packaging.

- Printing Presses: High-quality printing presses for vibrant and eye-catching designs on your paper packaging.

- Bagging Machines: Efficient machines for filling and sealing paper bags, optimizing productivity.

- Wrapping Machines: Automated wrapping machines for quick and uniform packaging of paper products.

Equipment for Plastic Bags Manufacturing

Explore our comprehensive range of equipment tailored for plastic bag packaging. We offer innovative solutions to enhance efficiency, consistency, and sustainability in our packaging operations.

Bag Forming Machine – Multifunction laminated bag making machine that can manufacture 3-side sealing bag, 3-side sealing with zipper bag, single film insert stand up bag and third film insert stand up bags.

Automatic Bag Making and Spout-Welding Machine – used to make bags, cut an angle and weld plastic spouts on the cut automatically. The bag-making and spout-welding can be done at the same time. It is suitable for the large pouches of drinks, sauce, washing liquid, hand washing liquid and sugar powder etc.

Flexible Pouch and Spout Automatic Sealing Machine – This machine is used to weld a plastic spout to a flexible pouch. It is suitable for packaging drinks, jelly, soy sauce, flavorings and cosmetics (milk, face mask) etc..

Die Cutting Machine for flexible Bag Making Machine – The flexible bag manufacturing machine’s auxiliary tool, the die cutting machine, produces stand-up irregular pouches and three-sided irregular bags.

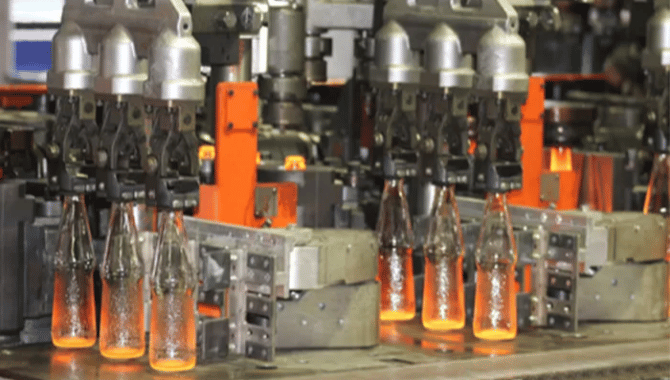

Glass Bottles Manufacturing Equipment

Manufacturing of glass bottles is done by two methods:

B&B (Blow and Blow) process equipment – The parison is created by using compressed air to form the neck finish and basic bottle shape. This method is for narrow-neck containers only

NNPB (Narrow Neck Press and Blow) process equipment -Press and blow is a two stage operation. This method is used for jars and tapered narrow-neck containers.

Equipment for Plastic Bottles Manufacturing

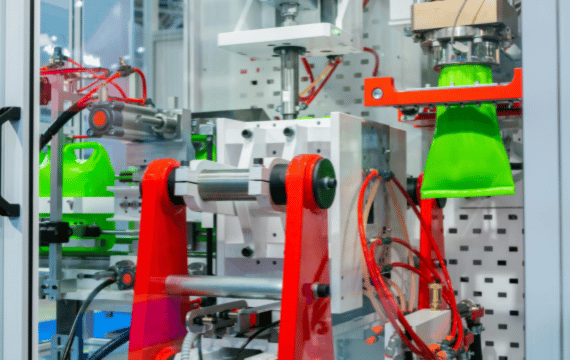

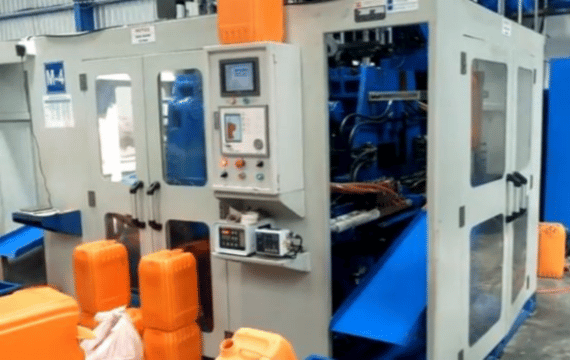

Extrusion Blow Molding Machines (EBM) – Characteristics unique to the EBM bottles include handles, labels molded in and offset necks. The types of plastic we commonly use for bottle production are HDPE, PVC, PC, PP, and PETG.

Injection Blow Molding Machines (IBM) – To make plastic bottles used for liquids but not carbonated ones. Popular material choices include; HDPE, PET, PP, PVC, LDPE.

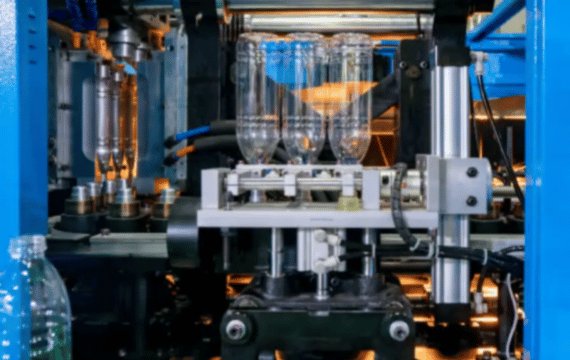

Injection Stretch Blow Molding Machines (ISBM) – Is used for PET plastic bottles in a transparent shiny finish and is considered the industry standard globally.

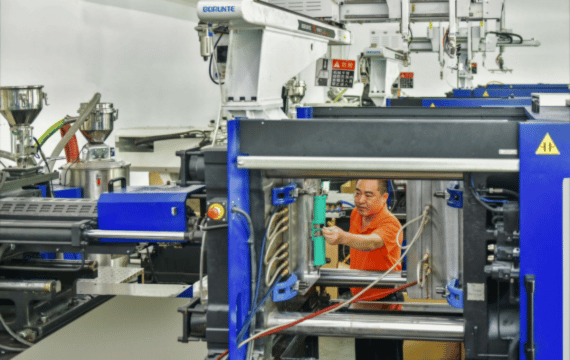

Injection Molding Machines (IMM) – This machine is being used for production molding of bottle lids or caps.

Rotogravure Printing Machine-Digital Printing Machines for Pouch. Flexographic Printing Machine, and Digital Printer For Carton Packaging

Co-Extrusion Blow Molding Machines – Bottles, tubes are commonly used in the food and cosmetics industries are good examples of co-extrusion blow molding.